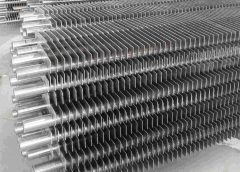

Fin Tubes or called finned tubes are a basic part of shifts warm recovery structure. The close to the association between the Finning improvement and the manufacturing plant licenses fundamental savings in packaging and payload in like manner as working capital lessening in context on “without a minute to save” inventory arrange.

In light of their increasingly basic warmth exchange a surface domain, they offer the broad potential to extra regarding materials and fill volumes. It has been seen that for Low finned cylinder units there are some perhaps positive conditions to put certain fluids, especially with high viscosities, in the shell side of warmth exchangers instead of the cylinder side.

General Configuration of a Fin Tube Exchanger

A finned cylinder heat exchanger will consistently have tubes with fins joined to the outside of them. Different gas streaming outside of the tubes, where the extra warmth exchange surface zone because of the finned cylinder, develops the glow transformation scale. For a crossflow finned tubes exchanger, the fins will ordinarily be broadened fins either indirect or square, have appeared in the photos in this part.

Most finned cylinder heat exchangers are crossflow, utilizing finned tubes to some degree like the upper pictures. For a counterflow or parallel stream fin tube exchanger, the fins ought to be longitudinal instead of winding, as appeared in the lower outline at the left. Finned tubes might be utilized as interior tubes in an encased warmth exchanger.

FIN TUBE MANUFACTURER

Fin Tubes are warm exchanger tubes mainly required to trade warm from a flowing fluid and cooling it someplace close passing air on the fins of the tubes. In evacuated fin tubes, the surface region of warmth trade is increased by virtue of the increased stature of the fins consequently causing it to finish up truly introduced to the flowing air. Moreover, in this system, the thickness of the fin is in like manner low causing the radiance trade to finish up increasingly incredible. The removed fin tubes are used mainly where the earth is damaging and the shine trade required is higher.

Introduction

For a fluid warmth exchanger, the utilization of a finned cylinder isn’t ordinarily required, in light of the manner in which that the glow exchange coefficient for the various sides of the glow exchange surface is honorably high. For an air heat exchanger, notwithstanding, where one of the liquids is air or some different gas. The airside warmth exchange coefficient will be much lower, so extra warmth exchange a surface territory. As in a Finned tubes manufacturer in Saudi Arabia exchanger is profitable. The general stream plan for a finned cylinder exchanger is ordinarily crossflowed. In any case, it can in like way be counterflow or parallel stream.

Improved features of Low finned tubes

Low finned tubes innovation can change sweeping shell and cylinder exchangers into minimized warmth exchangers. This is perfect for conditions with a low warmth exchange coefficient on the cylinder side. Similarly Low finned tubes coefficient out of the blue sides. The most grounded one can be utilized to build up a store drop Low finned tubes relationship. Which has starting late been utilized as a bit of estimation for exchanger measuring.

We offer you a wide game-plan of materials and can loosen up our offering. Whatever point to meet your particular needs with respect to warmth Low finned tubes conductivity, mechanical properties, or disintegration affirmation. In like way, a system for the ID of points of interest of Low finned tubes warm exchangers over plain cylinder units have been made. Low Finned tubes manufacturer in Saudi Arabia are starting at now open in copper-nickel, copper, steel, aluminum, titanium, and stainless steel.

The Advantages Of Finned Tubes

Exchanging heat from a hot fluid into a colder fluid through a cylinder divider is the reason an immense number of us use Finned tubes manufacturer in Saudi Arabia. For any circumstance, you may ask, what is the huge extraordinary situation from utilizing a finned cylinder? For what reason wouldn’t you have the decision to just use a standard cylinder to make this trade? Indeed, you can, for any circumstance, the rate will be much slower.

Choosing the privilege finned tubes

Our capacity to draw base tubes from our supply of more than 1,000 tons enables us to respond rapidly to customers’ requests and to remain aggressive with some other makers around the world. Profits’ finning office empowers various fin and tube material and size combinations to be produced. This gives us unparalleled adaptability and enables us to respond quickly to crisis orders.

The fins on a loop achieve two noteworthy capacities. To begin with, they fix the air as it interacts with the entering-air side of the curl. Ordinary procedure fans will, in general, convey air through a unit in a winding example. The fins fix this wavy air and permit the air an increasingly uniform way over the essential surface. Second, they really do some warmth moves of their own. The warmth move is taken from the tube to the fin, accordingly raising the general limit of the curl. This is the reason the fins are known as an auxiliary warmth move surface.